What is CMM inspection?

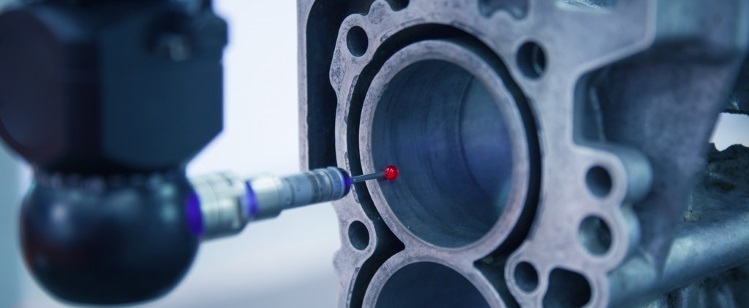

A coordinate measuring machine (CMM) is a device that measures the geometry of objects by using a contact probe to sense specific points on a physical surface. The machine compares the probe's position in a three-dimensional coordinate system (XYZ axes) to the specifications of the intended design. With these ultra-precise scans, you can assure an unerring product for the most meticulous uses.

Quality Control Solutions, Inc. offers the most advanced and highest precision inspection capabilities available. We can fulfill almost any dimensional & metallurgical inspection need your company may have. Such as:

- First Article Inspection (FAI)

- PPAP / ISIR’s

- SEM Capabilities

- Full Dimensional Layout

- Reverse Engineering

- Process Capability Studies & Support

- Surface Analysis

- 4 Axis Contact Measurement

- Roundness / Form / Cylindricity Testing

- Contour / Surface Measurements

- Part Per Print Measurements

- Gage R & R Studies

- CMM Measuring, Inspection and Programming

- High Volume Receiving & Inspection

- NDT and destructive testing

- Metallurgical Analysis

- Hardness Testing

- Fixture Qualifications

- 3D Optical Flatness / Surface Measurement

- CAD Import / Export Capabilities

All this and more… including onsite capabilities. Whether you need a full FAI or one of our many other inspection services, you can rely on MSI/PPT to perform a complete, independent, and documented physical inspection.

Why choose QCSI?

QCSI has been providing high-quality, USA-made products and inspection and calibration services with industry-standard accreditation for over 40 years. Companies in a wide variety of industries choose us because of our hands-on knowledge, commitment to customer service, and extensive selection of precision measuring devices and accessories to ensure that you will find the right equipment for any application. Contact us today for more information about our quality control devices and quality inspection instruments.

Scroll to Top

Scroll to Top