Product Features

-

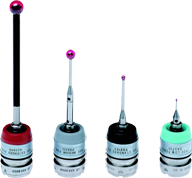

- Flexibility - Choose 1, 2 or all 3 sensors (Video, Touch Probe, Laser)

-

- Solid Granite Base

-

- Components machined from 6061-T6 aluminum

-

- Cross roller bearings

-

- Unique Arch Design - Minimizes Cantilever of Optics

-

- Fiber Optic Light Sources

-

- Motorized Zoom Lens

-

- Superior Color Image

-

- 27″ Widescreen LCD monitor with large live image.

-

- Custom Workstation

- 2 Year Warranty

Available Options

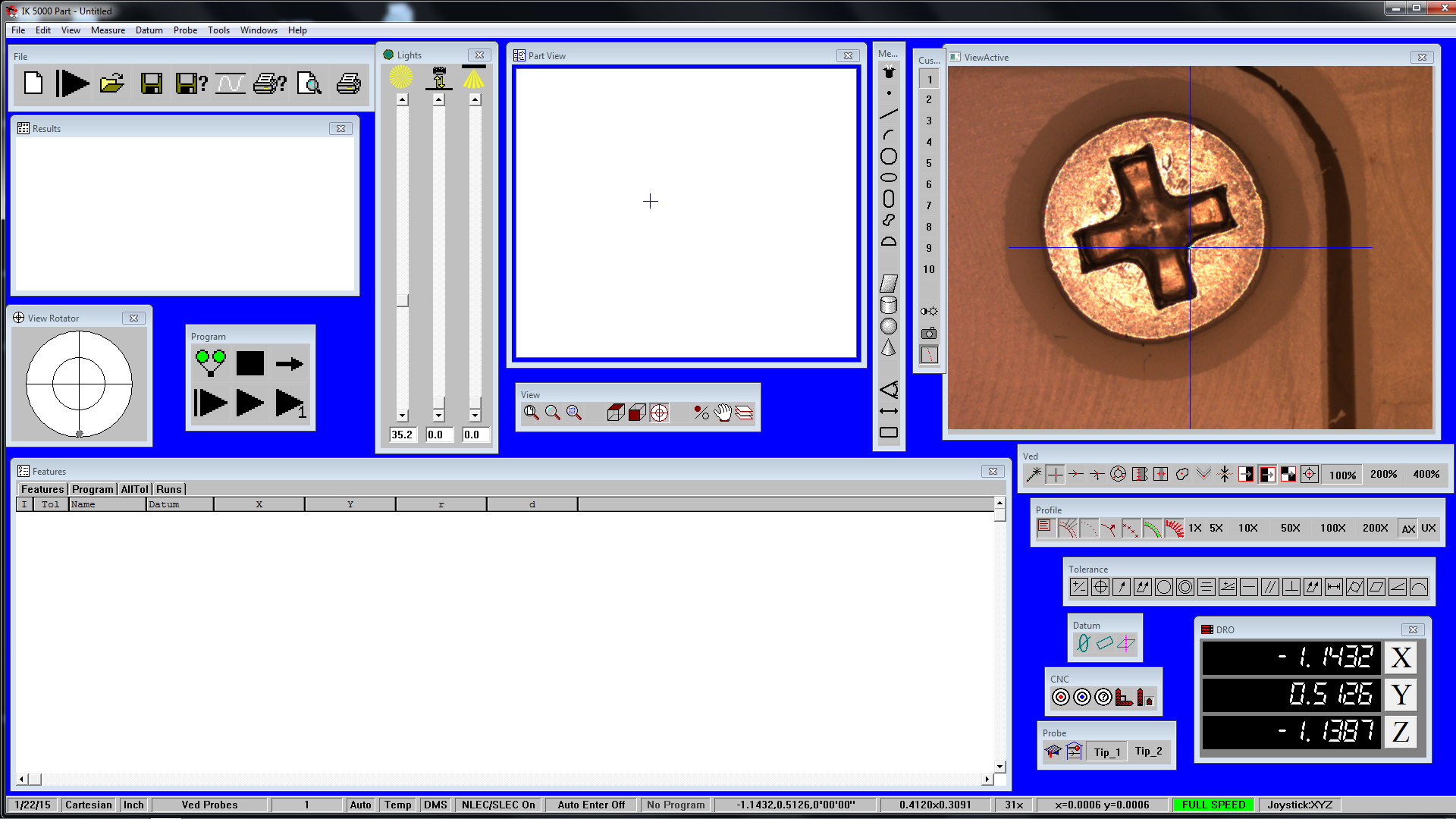

Intelligent Software

IK5000 advanced metrology software is the prime control interface for our precision multi-sensor measuring systems, providing a commanding solution to empower operators along every step of the measurement process.Powerful features reduce repetitive measurements and simplify complex work steps, with the ability to utilize Video Edge Detection (VED) for enhanced throughput. The IK5000 features intuitive drag-and-drop data fields, macros and database templates, plus programming and automation tools.

Highlights

- Precise measurement and inspection of 2D and 3D parts

- Intuitive interface and intelligent time-saving functions

- Drag and drop data fields, macros, database templates, programming

- Time-saving automation tools to accelerate measurement and complex workflows

- Import CAD files to automatically create part programs

- Integrated simple Statistical Process Control (SPC)

- Custom formulas

- Fitting to DXF files

- Software training and support by qualified application engineers

Specifications

| Model No. | SB24246 |

| Measuring Range (X,Y,Z) | 600mm x 600mm x 150mm (24″ x 24″ x 6″) 300mm (12″) Z-axis optional. |

| Measuring Stage | Anodized aluminum work surface with fixture holes and removable stage glass. DC stepper drives with variable speed joystick control. |

| Controller Software Options | IK 5000 or M3 |

| System Footprint | 50" x 41" x 70" 750 lbs |

| Load Capacity | 65 lbs |

| Magnification | Capable of up to 540x |

| Optics | 12:1 programmable zoom lens 0.5x, 1.5x and 2.0x lens attachments optional. |

| Illumination | Fiber Optic On-axis light, Bottom light, Ring light |

| Scale Resolution | 0.5 µm (0.00002"), 0.1 µm (0.000001") optional |

| Accuracy | (X or Y) E1 = 1.0 + 5L/1000 µm* (XY) Axis E2 = 1.5 + 5L/1000 µm* (Z) Axis E1 = 3.5 + 5L/1000 µm with standard auto focus zoom lens* E1 = 2.5 + 5L/1000 µm with optional 2.0x lens attachment* *L = measuring length in mm. Applies to thermally stable system at 20° C, maximum zoom lens setting, and evenly distributed 5 kg load. Depending on stage loading, accuracy of at maximum rated load may be different than the standard accuracy. |

| Camera | 1/2" format color CCD camera with 768 x 494 array |

| Computer | Industrial rack mount CPU with 27" display |

| Mounting | Custom built workstation |

| Warranty | 2 Year Warranty |

Scroll to Top

Scroll to Top